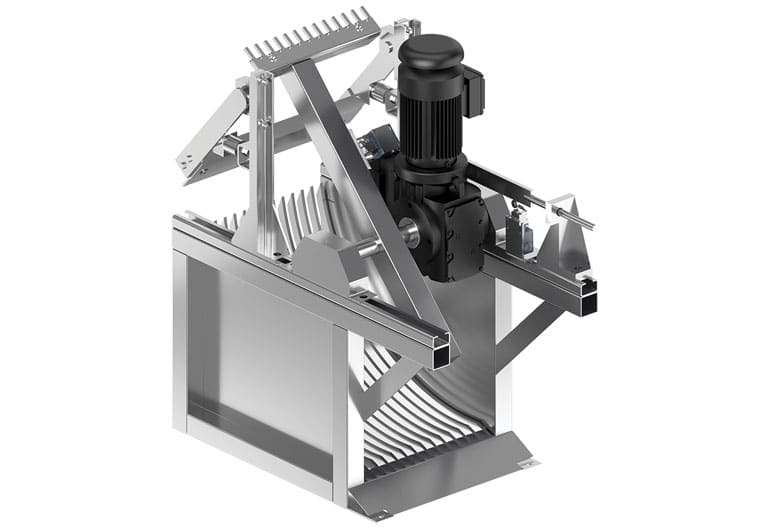

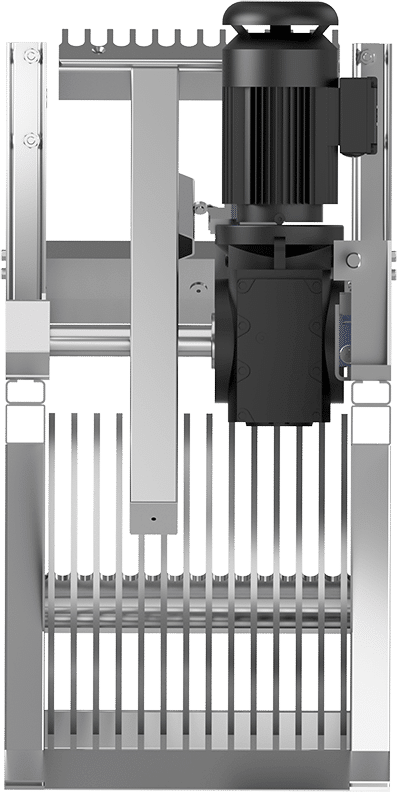

EnviroCurve

Medium to coarse screening

Storage of waste in a basket positioned downstream of the screen.

However, to match with specific applications or installations, it is possible to add a compacting zone for dewatering the waste (model SRS/P).

The screen space is cleaned by a comb mounted at the end of a scraping arm rotating around a horizontal axis.

1

2

3

4

5

6

7

8

Components

1

Rigid one-piece curved grid

2

One-piece chassis to house the components and ensure the screen sits on the concrete frame

3

Stainless steel arm with a comb at the end

4

Comb cleaning device

5

Waterproof and tropicalized gear motors

6

Alignment bearings to support and guide the rotation of the mechanism

7

Overload detection sensor

8

Electrical contacts

Advantages

- Fully automatic product.

- Flow range up to 800 m3/h

- Remarkable durability

- Requires minimum maintenance

- Very small footprint

- Overload sensor stops the device in case of blockage

- Supplied in galvanised steel or stainless steel

- Robust and reliable solution.

Option

- Aluminum safety cover

- Tailor-made to suit

- Galvanised steel screen

| Model ref | Bar width (mm) | Flow rate (m3/h) | Approx. Gross weight (kg) |

|---|---|---|---|

| DCM 5 | 400 | 0 - 150 | 300 |

| DCM 6 | 500 | 340 | |

| DCM 7 | 600 | 370 | |

| DCM 8 | 700 | 100 - 300 | 425 |

| DCM 9 | 800 | 470 | |

| DCM 10 | 900 | 200 - 800 | 500 |

| DCM 12 | 1100 | 400 - 800 | 575 |