EnviroKnead

Liming

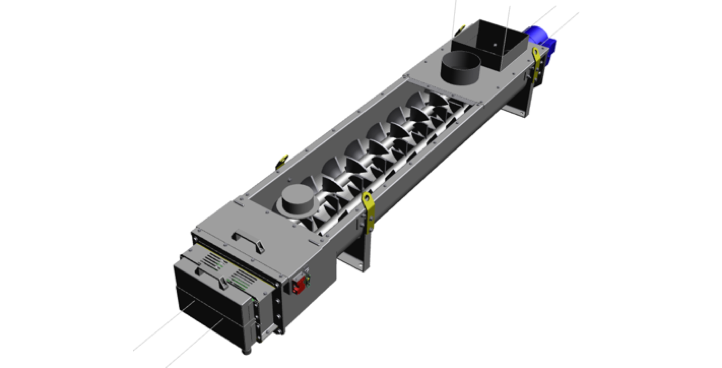

The Envirolime EVP mixers operate continuously according to the feed flow. They consist of two rotors around which pallets are welded. The shape and the inclination of these pallets as well as the interlacing of these pallets allow a homogeneous mixing of the products

The Envirolime pallet mixer is mainly used as a sewage treatment plant for sludge liming. This operation consists in mixing the sludge from the dewatering plant with lime.

1

2

3

4

5

6

7

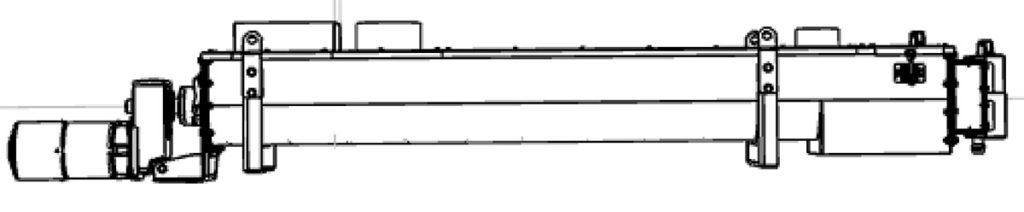

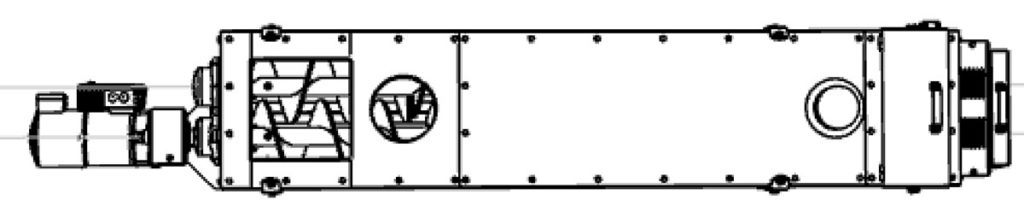

Layouts

1

Inlet hoppers

2

Blocking detector

3

Trough

4

Discharge hopper

5

Rotors with pallets

6

Cover

7

Transmission coupling

Specificities

- Closed unit

- Mixing efficiency

- Modularity

- Easy installation and maintenance

- Low maintenance costs

- Reliability and durability

Inlet and outlet

The feed outlet for the reception of the products to be mixed and the discharge outlet are custom made according to the configuration of the installation.

Mixing

The diameters of the rotors and the pallets are sized according to the total flow to be mixed. The length of the trough defines the mixing time. Standard dimensions have been fixed, but it is possible to adapt the length of the machines to adjust the contact time or to adapt to the environment. Moreover, in order to optimize the quality and the appearance of the mixture according to the nature of the products, the use of a speed variator is strongly recommended (both rotors are driven by a single motor).

Performances

| Models | |||

|---|---|---|---|

| EPV 200 | EPV 250 | EPV 300 | |

| Flow rate (m3/h) | 2 | 6 | 12 |

| Installed power | 2.2 | 2.2 | 3 |

Materials

Construction in stainless steel 304L or 316L

Rotors and pallets in special steel high resistance

Dimensions

| Overall dimensions in mm | |||

|---|---|---|---|

| Models | EVP 200 | EVP 250 | EVP 300 |

| Rotors diameter | 200 | 250 | 300 |

| Trough length | 2000 | 2500 | 3000 |

| Trough width | 450 | 530 | 620 |

| Trough height | 260 | 310 | 400 |