EnviroDuo

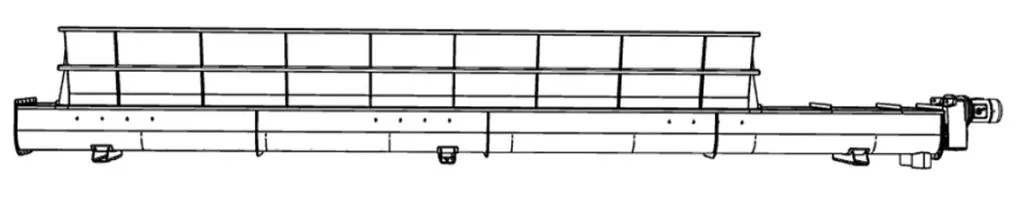

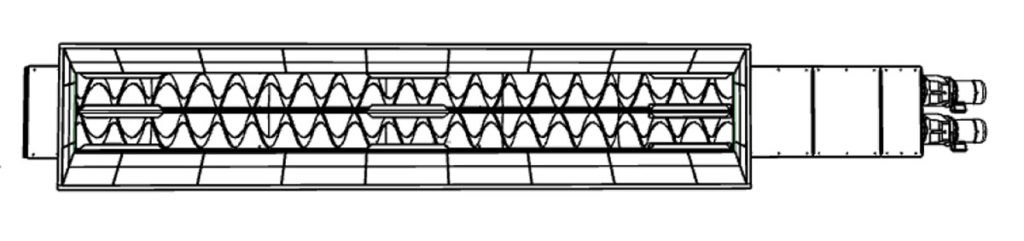

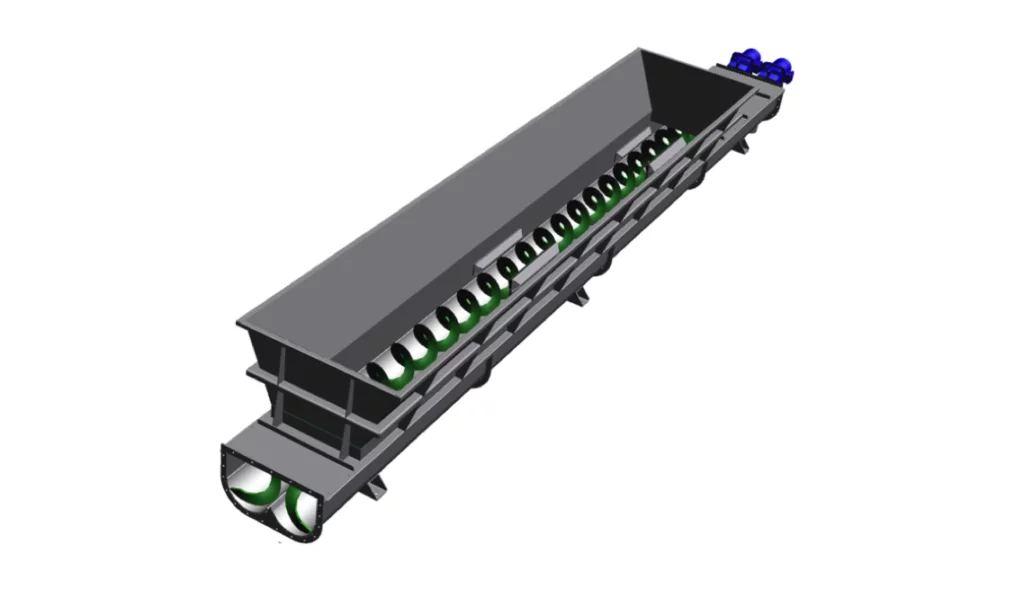

Multiple screws conveyor/extractor

The Enviroduo conveying and extracting unit is designed for difficult products such as sewage sludge.

Enviroduo double screws are commonly used for the recovery of sludge under filter press. This solution offers a large width in order to recover sludge cakes while preserving the height thanks to the use of screws of smaller diameters. The cakes break during their transfer and even better when using the option of notched screws(screw with axis). This is favorable for the proper operation of conveyors installed downwards.

Multi-screw technology is also used for the recovery of sludge stored in silo (Enviromulti).

1

2

2

3

4

5

1

Layouts

1

Trough

2

Conveyor Multispir MTS

3

Double screw

4

Covers

5

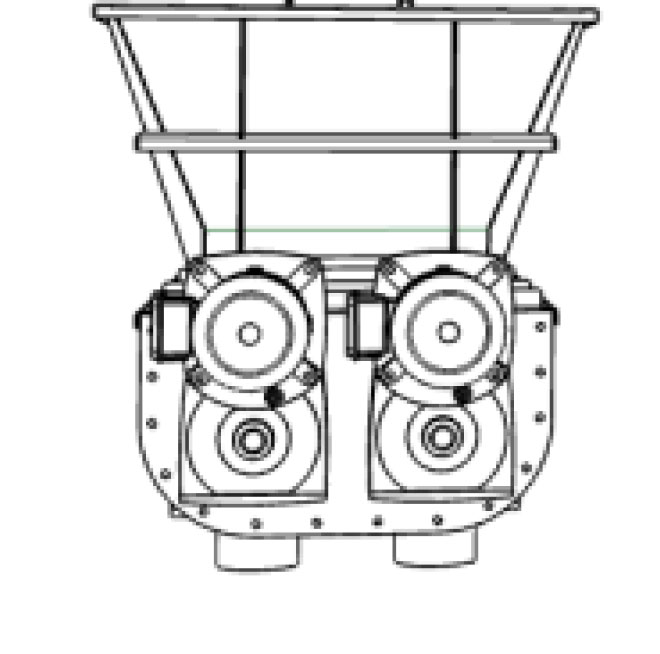

Motorisations

6

By-pass

7

Mobile cover

8

Bagging unit

Specificities

- Recovery of sludge under filter press

- Bottom silo extraction

- Screw with shaft and without

- Variable pictches

- Reliability and durability

Trough

For shaftless screws, the troughs are U-shaped and serve as a guide. For screws with axis, a flat bottom trough solution is generally used.

Discharge

The shape of the discharge case is modular according to the configuration of the implantation and according to the equipment chosen further for the transfer of the sludge.

Screw

The shaftless screws are laying on HDPE lining and are guided by the shape of the trough which keeps them in their axis. This is generally the solution chosen for screw extractors. The screws with axis are guided by bearings at the ends and intermediate bearings according to their length. This solution is well adapted in particular with notched screws.

Performances

| Flow rates(m3/h) | ||||||

|---|---|---|---|---|---|---|

| Models | MTS 200 | MTS 250 | MTS 300 | MTS 350 | MTS 400 | MTS 500 |

| Dewatered slude | Up to 100 m3/h depending on diameter, screw technology, rotation speed and other design criteria | |||||

Materials

Construction in stainless steel 304L or 316L

Screw in special steel high resistance or stainless steel 304L or 316L

Dimensions

| Overall dimensions in mm | ||||||

|---|---|---|---|---|---|---|

| Models | MTS 200 | MTS 250 | MTS 300 | MTS 350 | MTS 400 | MTS 500 |

| Dimensions | Design and manufacturing on demand | |||||