EnviroSlot

Static screen

The static screens are fed into a box at the rear of the machine. The effluents loaded with suspended matter are discharged overflowing over the entire width of the screen.

This technology is regularly used in the paper industry because the principle is particularly well suited for the separation of fibrous particles. This solution is also used in the slaughterhouse, tanneries, food and agri-food industries. Wherever you are looking for a static separation solution with no mechanical parts in motion, this technology can find its place. It is, in some cases, used for the screening of effluents at the inlet of the treatment plant.

The waste is collected at the bottom of the screen while the screened effluent is recovered in the lower part behind the screen.

1

2

6

7

3

4

5

8

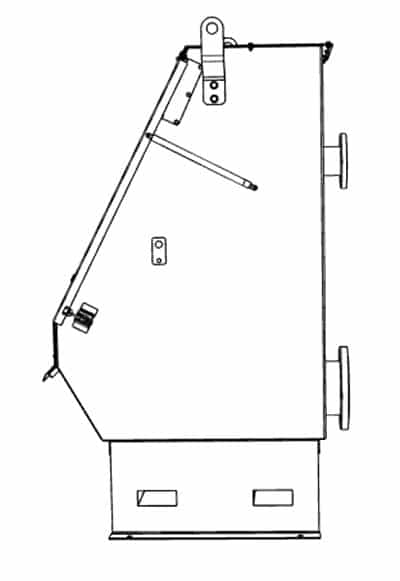

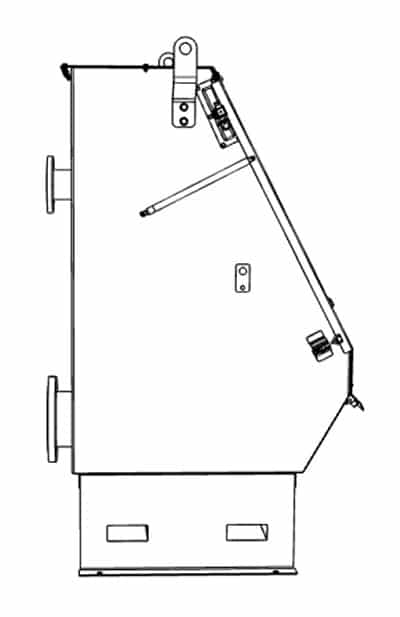

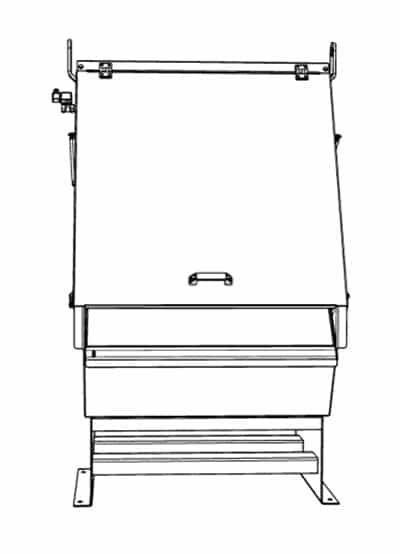

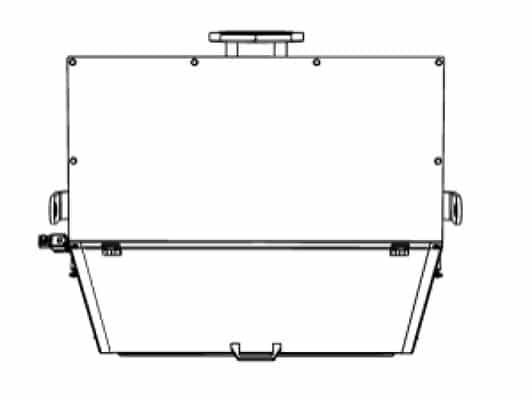

Layouts

1

Cover jack

2

Body frame

3

Washing ramp connection

4

Cover

5

Screen

6

Inflet flange

7

Outlet flange

8

Anti-splash cover

Specificities

- No moving parts

- No electrical consumption

- Separation by gravity

- Easy installation and maintenance

- Low maintenance costs

- Reliability and durability

Frame

The frame is made up of two main parts. One for the reception of the raw effluents which ensures the spill overflow on the top of the screen, and the other which receives the screeneded effluent.

Screen

The screen consists of trapezoidal wires in horizontal position which separates the suspended matter. The spacing between the wires defines the mesh and their trapezoidal shape avoids the retention of particles on the back of the screen.

Flanges

The machine is equipped with two flanges. One for feeding in the upper part of the machine and the other in the lower part, for evacuation of the effluent.

Performances

| Hydraulic flow rates (m3/h) | ||||||

|---|---|---|---|---|---|---|

| MESH (MM) | SLS 500 | SLS 750 | SLS 1000 | SLS 1250 | SLS 1500 | SLS 17500 |

| 0.25 | 34 | 50 | 67 | 84 | 101 | 117 |

| 0.5 | 38 | 56 | 75 | 94 | 113 | 131 |

| 0.75 | 48 | 71 | 95 | 119 | 143 | 166 |

| 1 | 53 | 79 | 105 | 131 | 158 | 184 |

| 1.5 | 64 | 95 | 127 | 159 | 191 | 222 |

Flow rates are reported as information for an effluent loaded from 200 to 500 mg / l. For any request please consult us

Materials

Construction in stainless steel 304L or 316L

Dimensions

| Overall dimensions in mm | ||||||

|---|---|---|---|---|---|---|

| MODELS | SLS 500 | SLS 750 | SLS 1000 | SLS 1250 | SLS 1500 | SLS 1750 |

| WIDTH | 1100 | 1350 | 1600 | 1850 | 2100 | 2350 |

| HEIGHT | 1850 | |||||

| LENGTH | 1100 | |||||