Formic Acid Dosing Station

Skid for descaling fine bubble aeration grids

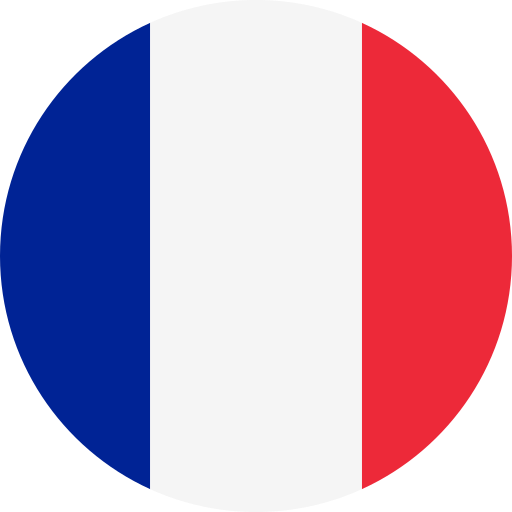

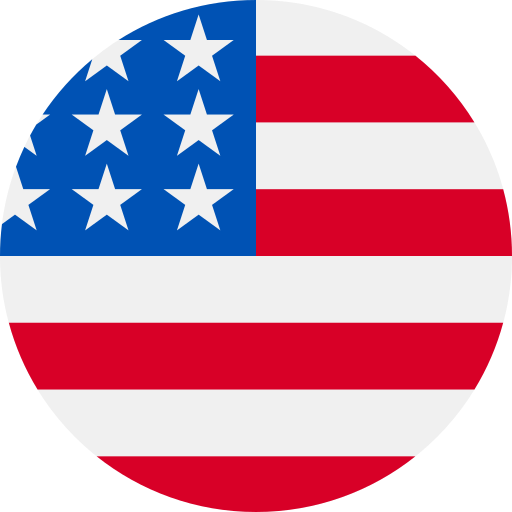

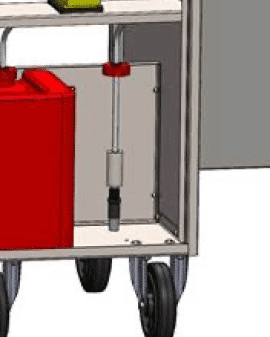

PUSHCART manufactured in Stainless

Steel and complete with the following

Storage box in HDPE

PVDF lined dosing pump

Flexible delivery hose 25m in pvc

(reinforced with polyester fibres)

Spray nozzle in stainless steel

Electrical socket 230v in abs

Formic acid canisters in hdpe

Suction system

Control box in coated steel

A pair of chemical-resistant gloves

A protective visor

A pressure gauge and its connection

Main’s adapter male/male

Rental and services the solution for the maintenance of your diffuser membranes

Please call on our Service Department and use their expertise. Europelec offers a complete Cleaning Service including:

- Rental of the formic acid pumping Cart

- The supply of formic acid with the quantity required to Completely clean your Diffusers

- The assistance of our technicians on site to conduct

- Injection cleaning with the Formic Acid Cart and associated pipework.

The pressure gauge supplied allows a pressure drop reading to be taken.

The control panel of the formic acid injection trolley is equipped with a timer which allows the pump to be switched off automatically.

Our operating instructions provide information on how to calculate the cycle time and the amount of acid required.

The injection is done by means of a specific injection nozzle connected to the pipework and this allows safe transfer of the formic acid. A stainless-steel cover protects the of the pump and control equipment within the troller

A wheel locking system is fitter to the front wheels of the trolley

This mobile descaling system can be connected to your installation. The cart makes it easy to transport. The unit pumps the formic acid from its holding tank and sends it via the delivery pipe to the underside of the membranes, and this has excellent distribution qualities.

It is recommended to descale the diffusers regularly, without waiting for a significant increase in pressure drop. Weekly, monthly, or annually, the frequency of descaling varies according to the composition of your effluent.

- A complete technical manual is included with the sale of this equipment for its use

- Transport

- How to start it up

- Settings

- Maintenance

- Dosage advice

- Precautions for use

- Carrying out the injection phase

- The protocol for injecting formic acid into the fine bubble aeration system.

Clogging of membranes is linked to carbonation, i.e., the deposition of calcium carbonate, a major component of limestone, or – more rarely – of calcium phosphates. It results in either biofouling or clogging of the micro per- forations within the diffusers’ membranes. Blocking is always a possibility when using a fine bubble membrane aeration system.

In the presence of hard water or effluents loaded with calcium or magnesium carbonates. A formic acid injection device is therefore necessary to limit the effects of membrane blocking.

Without regular acid injection, carbonate deposits can lead to significant increases in head loss and reduce the treatment perfor- mance. This cleaning method reduces the pressure drop whereas if your do not clean the resulting increasing pressure drop will a cause the energy bill to escalate.

To maintain the performance of your membranes and prolong their life, it is recommended to periodically inject formic acid into the air lines, without waiting for the increase in pressure drop to which can become damaging. This is the most important consideration regarding protecting your installation and guarantee a longer life. The acid transferred into the diffusers will dissolve the deposits linked to carbonation.